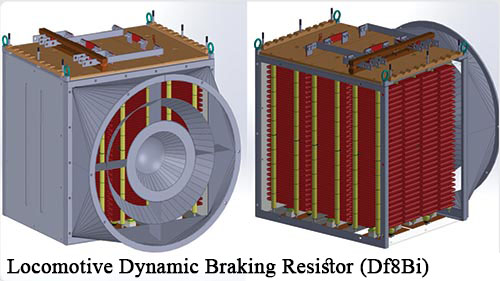

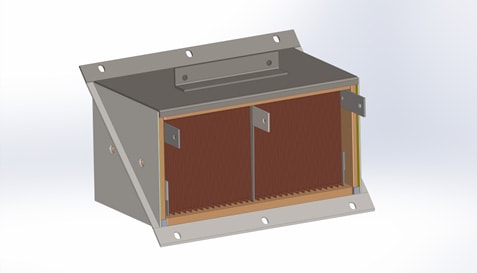

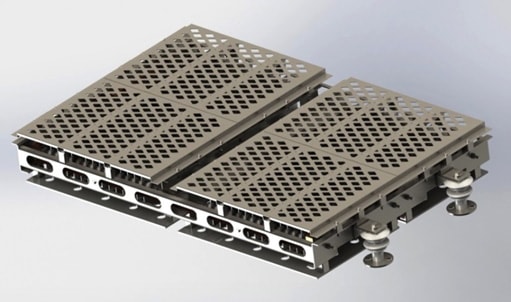

Dynamic Braking Resistor (DBR) is used in the rail industry brake system, traction motors, heavy machinery in mining industry, cranes, conveyors, elevators, and etc. Dynamic Braking Resistor results in loss of inertia and rapid engine stopping.

When the DC motor is stopped, this motor is isolated from the power supply and enter the current generating range due to motor inertia. At this time, DBR is connected to the DC motor as a load consuming device, and the energy is wasted as heat resulting the engine to be stopped quickly.

In AC motors, by cutting off the stator from the power supply, there is still a high inertia in the load and the rotor, and the motor enters the regeneration mode and motor stops with the energy produced in the DBR. Additionally, DBR resistance prevents over-voltage caused by regeneration mode on the inverter.

Advantages of using Dynamic Braking Resistors:

- Quick stop of AC and DC motors

- Avoid raising of the temperature during engine braking

- Maintaining the voltage in the motor working range and preventing the overvoltage tripping of the inverter

- Reducing the risk of mechanical brake failure due to temperature rise

- Reducing the damage of the parts joined to mechanical brakes

- Increasing the life of mechanical brake components

- Increasing the reliability of the braking system