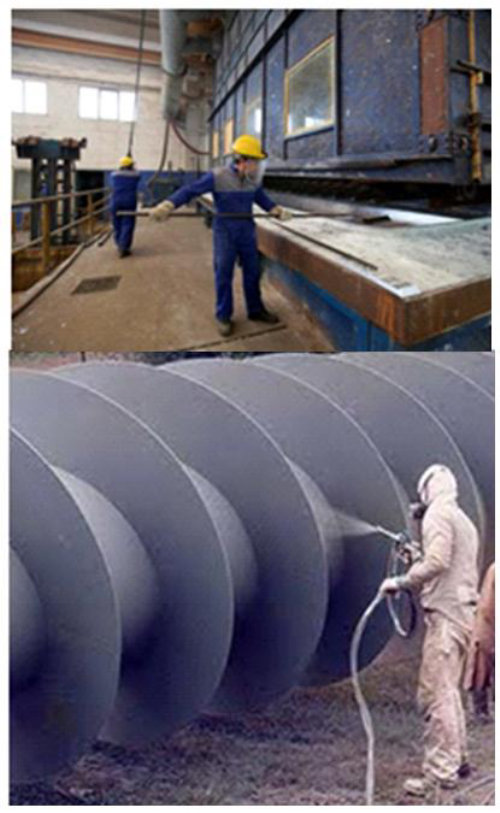

Galvanizing procedure

Like most coating processes the secret to achieving a good quality coating lies in the preparation of the surface. Following items describe the steps for metal surface preparation before starting the painting on surface. This can definite total in 3 steps:

- Washing and cleaning the surface of iron parts with degreasing solution by hand. This step helps to better result in the next step.

- Moving metallic components in phosphate processing part and washing the surface with solution of phosphate and water by hand in all side.

- Drying the water and wet for 20-120 min. (drying time must not be less than 20 min)

Painting procedure

After the preparation, surface painting steps shall be started. Procedure that use for painting is inclusive 2 steps.

- spray the polyester powder type color with electrostatic gun to surface with regulated voltage and suitable distance between gun head and surface.

- move the painting surface in the warm cabin for 10-15 min. (Tem. Approximately190-210◦C)

Quality Control Procedure

- Visual check:

Complete cured coating surface with suitable film thickness checked by naked eyes, such as bit, crater, haze, and flow-out.

2. Film thickness DIN EN ISO 2360:

Film thickness tester describes a method for non-destructive measurements of the thickness of non–conductive coatings on electrically conductive (generally metallic) basis materials, using amplitude–sensitive eddy current instruments.

3. Color ISO 7724:

Color RAL Coating film shall be selected according to the document and owner request.

4. Adhesion Test DIN EN ISO 2409:

In the paint industries the principle concern with respect to adhesion is that of a coating remaining firmly attached to the substrate. One simple test to evaluate this is the cross-cut adhesion test. In this test the painted panel is subjected to a series of cross cuts at right angles to each other on the surface each series at a distance of 2mm apart. The amount of paint which is removed by brushing the surface is compared to a set of standards. This test is carried out using adhesive tape which is attached to the surface and then pulled away.